1. What is a fine pitch nut?

The fine pitch nut is a nut with fine threads. Its pitch is smaller and more delicate than that of conventional nuts. This makes it unparalleled in adaptability in various occasions. When conventional nuts cannot meet the needs of precision adjustment, it becomes the key to solve the problem. It always shines in mechanical or electrical equipment that requires tight fit and no room for error. Whether it is advanced manufacturing such as precision instruments and watches, or high-tech fields such as aerospace, fine pitch nuts have won people’s trust with their unique advantages.

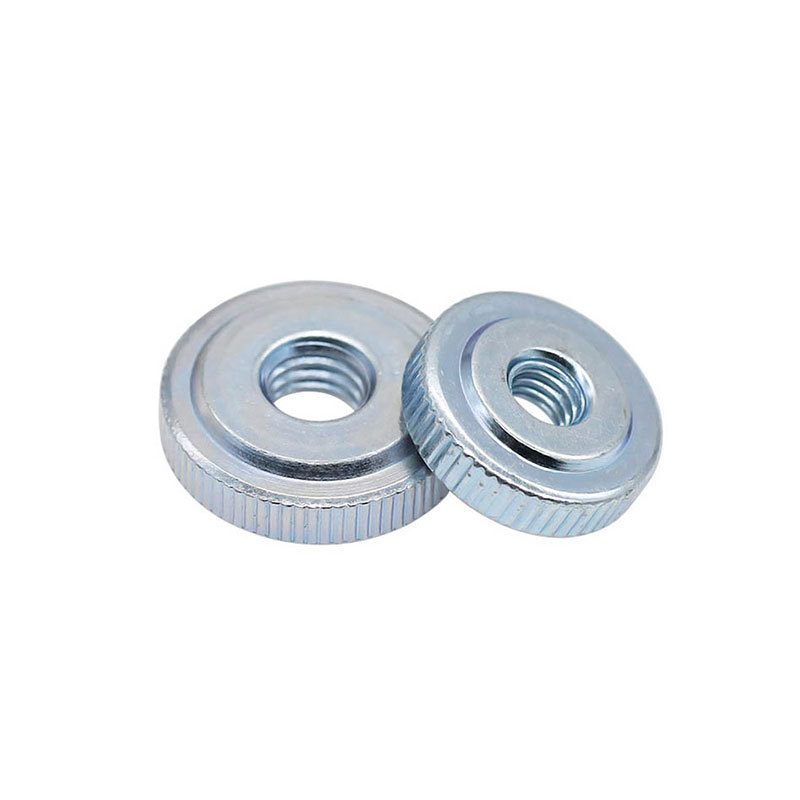

2. Fine pitch nut

Taking the M12 fine pitch nut as an example, its pitch has three specifications: 1.5mm, 1.25mm and 1mm.

1.5mm fine pitch nut is mainly used in occasions requiring medium locking force,

1.25mm and 1mm fine pitch nuts are suitable for occasions requiring higher locking force. Since the pitch of fine pitch nut is smaller, its locking torque is relatively small, which can better protect the thread and reduce wear and damage.

3. Where to use fine pitch nuts

- Where preload is required, because fine thread has higher self-locking property than coarse thread, the preload is also larger.

- Where high precision is required, such as threads on seals.

- Where the design is restricted, such as where a compact structure is required.

- When used as a tooling design transmission part, fine thread can be used when the precision transmission shaft has sealing requirements.

4. The difference between coarse and fine threads of nuts

The coarse and fine pitch of a nut refers to the pitch of the nut. Generally speaking, nuts are divided into coarse pitch and fine pitch. The pitch of coarse pitch is greater than that of fine pitch. The differences between coarse pitch and fine pitch are mainly in the following aspects:

- The helix angle of fine thread is smaller, which is more conducive to the self-locking of thread, so fine thread is generally used in places where loosening is required.

- The pitch of fine thread is small. On the same thread length, more threads are screwed in, which can reduce fluid leakage, so it is used in places where sealing is required.

- Coarse thread has fewer threads of the same length, and the cross-sectional size of each thread is larger, which is better for bearing large tension and impact.

- Fine thread can also play a role of fine adjustment due to the advantage of small pitch.

- Different application range: coarse thread nut is mainly used to connect thicker workpieces, while fine thread nut is suitable for connecting thinner workpieces.

- Different bearing capacity: coarse thread nut has greater bearing capacity than fine thread nut and can withstand greater torque.

- Different thread depth: coarse thread nut has deeper thread than fine thread nut, so it is easier to lock and is suitable for more reliable connection.

5. Application of coarse and fine threads of nuts

The coarse and fine threads of the nut are selected according to the requirements of different workpieces, and generally according to the requirements of the working environment. The following are some common application scenarios:

- Mechanical equipment installation: In mechanical equipment and structures, nuts are often needed for connection. Coarse pitch nuts are generally used to connect thicker parts of the structure, while fine pitch nuts are used to connect thinner parts.

- Automobile maintenance: In automobile maintenance, nuts often need to be replaced. At this time, coarse pitch nuts or fine pitch nuts can be selected according to the specific situation.

- Home decoration: In home decoration, nuts are also a kind of fastener that must be used. Generally, coarse pitch nuts or fine pitch nuts are selected according to the material of the furniture and the amount of force it needs to withstand.