Definition of minimum margin

The specification table of pressure riveting fasteners has a column of minimum margin, such as:

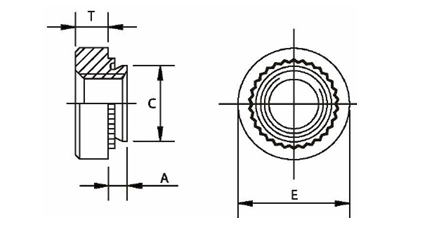

Metric specification table(unit:mm)

| Thread | Type | thread size | Specification Code | A | Minimun plate thickness | plate mounting hole size +0.08 | C -0.1 | E ±0.25 | T ±0.1 | tooth thickness ±0.05 | Tooth outer diameter ±0.1 | Minimum margin | ||

| carbon steel | stainless steel | stainless steel hardened | Max | |||||||||||

| M2*0.4 | S | CLS | SP | M2 | 0 | 0.76 | 0.8-1 | 4.25 | 4.22 | 6.35 | 1.5 | 0.35 | 5.25 | 4.8 |

| 1 | 0.97 | 1 | 0.45 | 5.25 | ||||||||||

| 2 | 1.37 | 1.4 | 0.5 | 5.25 | ||||||||||

What does minimum margin mean?

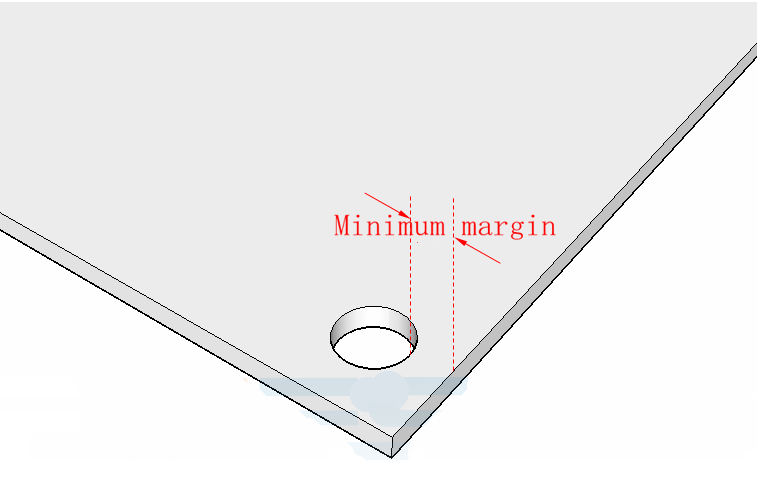

The definition is as follows: “margin” refers to the distance from the circular edge of the plate hole (quadrant point) to the outer edge of the workpiece, and “minimum margin” refers to not less than this distance. The following pictures are attached:

Minimum margin: