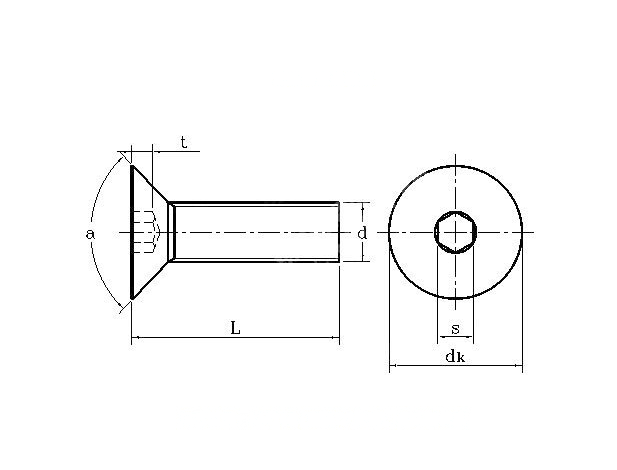

DIN7991 flat head hexagon screw head is a 90 degree cone shape, the middle is concave to the hexagon, also known as countersunk head hexagon.

Flat head hex socket for the workpiece surface is not allowed to stick out. Used in machinery, high-speed rail, mould such as above.

The production process of flat head inner hexagon is made of one die and two cold upsetting machine, and it can be rubbed by automatic tooth rubbing machine.

Countersunk hex socket screws table drawings and specifications

| The nominal diameter C | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | |

| Pitch p | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | |

| length B | 8-40 | 8-40 | 10-60 | 12-60 | 16-100 | 20-100 | 25-100 | 25-100 | 30-100 | 30-100 | 30-100 | 35-100 | 35-100 | |

| dk | max | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| s | intended size | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.18 | 10.175 | 12.212 | 12.212 | 14.21 | 14.212 | |

| min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.03 | 10.025 | 12.032 | 13.032 | 14.03 | 14.032 | |

| t | max | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

| a | max | 92° | 62° | |||||||||||

| min | 90° | 60° | ||||||||||||

Material of Countersunk hex socket screws

| Material | Element Name and Chemical Composition (%) | |||||||

| Carbon (C) | Manganese (Mn) | Silicium(Si) | phosphorus(P) | Sulfur (S) | Nickel (Ni) | Molybdenum (Mo) | Chromium (Cr) | |

| SUS304 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 8.00-11.00 | – | 17.00-19.00 |

| SUS316 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 10.00-14.00 | 2.00-3.00 | 16.00-18.00 |

Performance of countersunk hex screws

| sort | performance rate | diameter of screw | strength of extension | yield strength Mpa | elongation | proof stress |

| A2 | 50 | ≤39 | 500 | 210 | 0.6d | 500 |

| A2 A4 | 70 | ≤24 | 700 | 450 | 0.4d | 700 |

| A4 | 80 | ≤24 | 800 | 600 | 0.3d | 800 |

Countersunk hex screw torque standard

| Thread | performance rate | ||

| A2-50 | A2-70 | A4-80 | |

| Torque of failure | |||

| M1.6 | 0.15 | 0.2 | 0.24 |

| M2 | 0.3 | 0.4 | 0.48 |

| M2.5 | 0.6 | 0.9 | 0.96 |

| M3 | 1.1 | 1.6 | 1.8 |

| M4 | 2.7 | 3.8 | 4.3 |

| M5 | 5.5 | 7.8 | 8.8 |

| M6 | 9.3 | 13 | 15 |

| M8 | 23 | 32 | 37 |

| M10 | 46 | 65 | 74 |

| M12 | 80 | 110 | 130 |

| M16 | 210 | 290 | 330 |