DIN933 outer hexagonal screw as the name suggests that the head is hexagonal, also called hexagonal screw. DIN933 screw part applies to GB5783, attention is applicable, they are still the same, the main size in principle can be instead of using each other, but DIN933 and GB5783 still have a little difference, for example, the M8, M10, M12, M20 head size is a little difference, That is to say, the head of GB5783 is a little smaller than the head of DIN933. You can’t see it with the naked eye, and the best way to measure it is with a caliper or something.)

Hexagonal screw also 1/2 tooth and tooth completely two kinds. Also divided into three levels, class A, B, C, C grade hexagonal screw is one of the most commonly used, and A grade B level lower than cost, C level processing precision is coarser, class A and class B, the machining accuracy is higher, the natural cost is higher, it also depends on how to use the customer, class C in the request is not high, Grades A and B are used for high assembly accuracy.

Hexagonal screw thread and cent two kinds of coarse thread and fine teeth. The root strength of coarse threads is high. High precision fine thread.

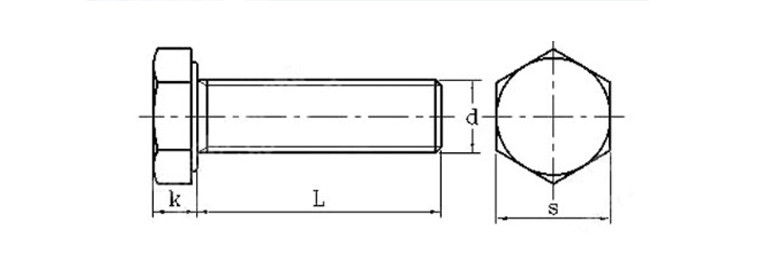

DIN933 hexagonal screw drawings and standard

| Diameter d | Pitch p | k | s | Length L | |||||

| A Grade | B Grade | max | A Grade | B Grade | |||||

| max | min | max | min | min | |||||

| M4 | 0.7 | 2.92 | 2.62 | 3 | 2.8 | 7 | 6.78 | 6.64 | 8-40 |

| M5 | 0.8 | 3.65 | 3.35 | 3.74 | 3.26 | 8 | 7.78 | 7.64 | 8-65 |

| M6 | 1 | 4.15 | 3.85 | 4.24 | 3.76 | 10 | 9.78 | 9.64 | 10-150 |

| M7 | 1 | 4.95 | 4.65 | 5.04 | 4.56 | 11 | 10.73 | 10.57 | 10-150 |

| M8 | 1.25 | 5.45 | 5.15 | 5.54 | 5.06 | 13 | 12.73 | 12.57 | 12-200 |

| M10 | 1.5 | 6.56 | 6.22 | 6.69 | 6.11 | 17 | 16.73 | 16.57 | 16-200 |

| M12 | 1.75 | 7.68 | 7.32 | 7.79 | 7.21 | 19 | 18.67 | 18.48 | 20-200 |

| M14 | 2 | 8.98 | 8.62 | 9.09 | 8.51 | 22 | 21.67 | 21.16 | 25-200 |

| M16 | 2 | 10.18 | 9.82 | 10.29 | 9.71 | 24 | 23.67 | 23.16 | 25-200 |

| M18 | 2.5 | 11.72 | 11.28 | 11.85 | 11.15 | 27 | 26.67 | 26.15 | 30-150 |

| M20 | 2.5 | 12.72 | 12.28 | 12.85 | 12.15 | 30 | 29.67 | 29.16 | 30-150 |

| M22 | 2.5 | 14.22 | 14.35 | 14.35 | 13.65 | 32 | 31.61 | 31 | 30-150 |

The material of hexagon screws, standard performance and torque

| Material | Element Name and Chemical Composition (%) | |||||||

| Carbon (C) | Manganese (Mn) | silicon(Si) | Phosphorus (P) | Sulfur (S) | Nickel (Ni) | Molybdenum (Mo) | Chromium (Cr) | |

| SUS304 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 8.00-11.00 | – | 17.00-19.00 |

| SUS316 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 10.00-14.00 | 2.00-3.00 | 16.00-18.00 |

performance

| category | performance rate | diameter of thread | strength of extension | yield strength Mpa | elongation | proof stress |

| A2 | 50 | ≤39 | 500 | 210 | 0.6d | 500 |

| A2 A4 | 70 | ≤24 | 700 | 450 | 0.4d | 700 |

| A4 | 80 | ≤24 | 800 | 600 | 0.3d | 800 |

Standard of torsion

| Thread | Performance rate | Performance rate | ||

| A2-50 | A2(A4)-80 | A4-80 | ||

| Damage to the torsion | ||||

| M1.6 | A2-50 A2-70 A4-70 A4-80 | 0.15 | 0.2 | 0.24 |

| M2 | 0.3 | 0.4 | 0.48 | |

| M2.5 | 0.6 | 0.9 | 0.96 | |

| M3 | 1.1 | 1.6 | 1.8 | |

| M4 | 2.7 | 3.8 | 4.3 | |

| M5 | 5.5 | 7.8 | 8.8 | |

| M6 | 9.3 | 13 | 15 | |

| M8 | 23 | 32 | 37 | |

| M10 | 46 | 65 | 74 | |

| M12 | 80 | 110 | 130 | |

| M16 | 210 | 290 | 330 | |

The purpose of hexagon screws

Hexagon screws are widely used in construction, railway, machinery industry and other fields.