Fasteners are commonly used parts in engineering, used to connect and fix various mechanical equipment and components. Since fasteners are generally made of metal and are easily affected by oxidation and corrosion, maintenance and rust prevention are very important to extend their service life and ensure their normal operation. This article will introduce several common fastener maintenance methods and measures to extend their service life from the perspective of rust prevention.

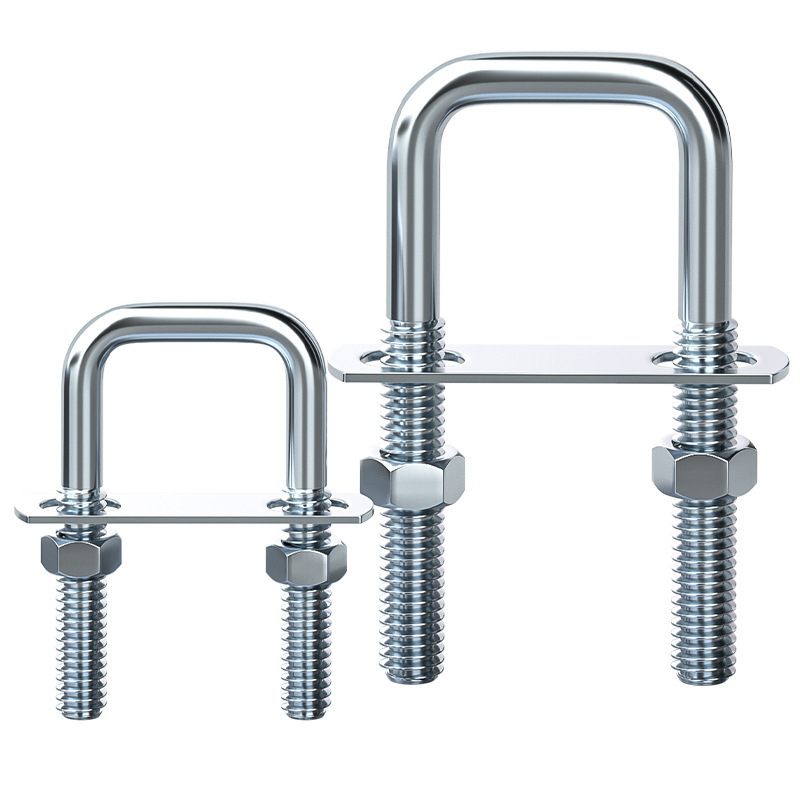

First, choose the right material. There are many kinds of materials for fasteners, and different environments and applications require different materials to make fasteners. Generally speaking, stainless steel fasteners are more commonly used because stainless steel has good corrosion resistance. In some high humidity, acid and alkali environments, the use of stainless steel fasteners can effectively prevent corrosion and rust.

Second, pay attention to the storage environment. Fasteners are susceptible to oxidation and corrosion during long-term storage or unused periods. Therefore, the following points should be noted during storage: First, avoid humid environments. Fasteners should be stored in a dry place and avoid exposure to humid environments. Second, avoid contact with other metals. Contact between different metals may cause electrochemical reactions, leading to corrosion of fasteners. When storing fasteners, try to store different types of fasteners separately. Try to avoid fasteners from contact with air. Fasteners can be placed in sealed bags and then placed in storage boxes to reduce oxygen contact.

In addition, perform regular maintenance. Regular maintenance is very important to extend the service life of fasteners. Maintenance includes the following aspects: First, clean regularly. Use a clean cloth or paper towel to wipe the dirt and dust on the surface of the fastener to avoid dust accumulation. Secondly, apply rust inhibitor regularly. Rust inhibitor can effectively reduce the oxidation and corrosion of fasteners. After cleaning, apply a special rust inhibitor to the fastener to protect its surface. Note that before applying the rust inhibitor, the dirt on the surface of the fastener needs to be cleaned, otherwise the rust inhibitor may not be effectively attached to the surface of the fastener. Regular inspection and replacement. Regularly check whether the fasteners are damaged, deformed or loose, and replace the necessary fasteners in time to ensure the normal operation of the equipment and components.

In addition, some other measures can be taken to extend the service life of fasteners. For example, install fasteners correctly. During the installation of fasteners, tighten them according to the specified installation torque to avoid over-tightening or over-loosening. Over-tightening may cause damage to the fasteners, while over-loosening may cause loosening. In addition, sealing gaskets or sealants can be added to improve the rust resistance of fasteners. Proper installation of these sealing materials can reduce the erosion of fasteners by oxygen and moisture. In addition, when using fasteners, pay attention to reducing impact and vibration to avoid spilling liquid or particulate matter from entering the connection parts of the fasteners.