Self clinching nut, also known as rivet nut, self-fastening nut, is a nut applied to sheet metal or sheet metal, the shape is round, one end with embossing teeth and guide groove. The principle is to press into the preset hole position of the sheet metal through the embossed teeth, generally speaking, the aperture of the preset hole is slightly less than the embossed teeth of the riveted nut, and the pressure makes the embossed teeth of the riveted nut squeeze into the plate, resulting in plastic deformation around the hole, and the deformation is squeezed into the guide slot, resulting in the locking effect.

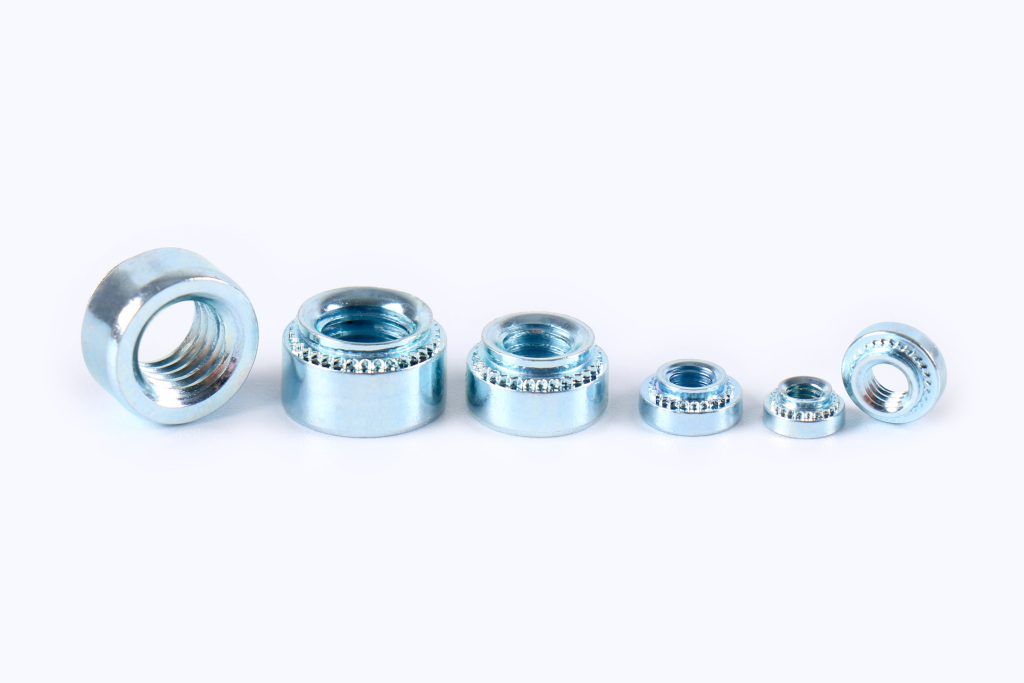

This is what it looks like:

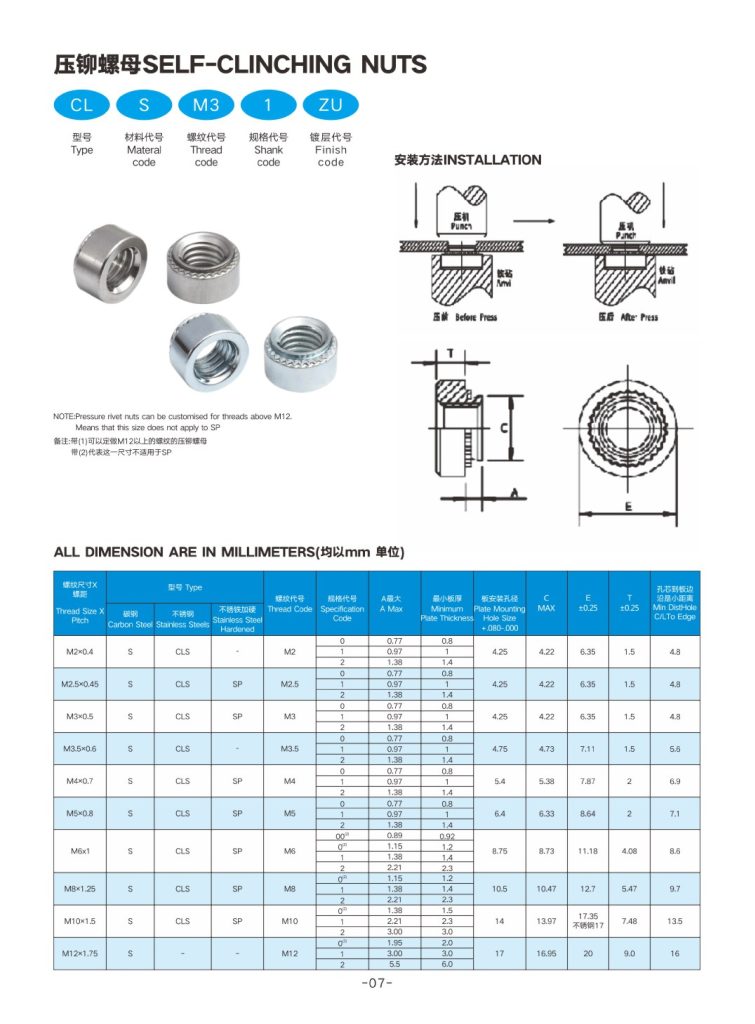

Pressure riveting nuts are divided into fast cutting steel pressure riveting nuts S type, stainless steel pressure riveting nuts CLS type, stainless iron pressure riveting nuts SP type and copper, aluminum pressure riveting nuts CLA type, respectively, should be used in different environment. Specifications are usually from M2 to M12. The above figure is S-type, representing the material of carbon steel surface galvanized

There is no unified national standard for rivet nuts, which are often used in the chassis cabinet and sheet metal industry.

Type:

S series, CLS series, SP series pressure riveting nuts, for the installation of internal threads to clear metal products, provide a simple method, played a reliable fixing role, small and delicate nuts, so that one side of the plate is perfectly inserted processing, installation, just insert the nut into the hole of the metal plate, with pressure to complete the inlaying strong function.

M4-1 CLS-M4-1 CLS-M4-2 CLSS-M5-0 CLSS-M5-1 CLSS-M5-2 CLS-M6-0 CLS-M6-1 CLS-M6-2 CLS-M8-1 CLS-M8-2

Application advantage:

1, the back of the plate to keep completely embedded;

2, small and compact, suitable for all electronic or precision equipment;

3, high torque resistance;

4, the equipment is convenient, just simple pressure riveting;

5, the specification series, can meet a variety of design requirements.

Application Technical Guide:

1, S series of pressure riveted nuts using free cutting iron, after heat treatment performance treatment, CLS series of pressure riveted nuts using easy to cut stainless steel, the surface is not treated.

2, low carbon steel plate hardness must be less than 70RB, stainless steel plate hardness must be less than 80RB.

3, suitable for various thickness of the plate, the minimum thickness of 0.8mm, the use must be based on the thickness of the plate and nut specifications, in order to determine the tail number Z corresponding to the size of A, the user according to the thickness of the plate according to the tail number in the table sample ordering;

4, according to the aperture size to be precisely controlled, according to the tolerance size of 0-+0.075mm processing, it is best to punch, the nut should generally be installed from the “disconnect” surface of the plate. The installation process is generally achieved through a “press riveting” operation and must not be percussive.

Production technology:

The production process of the riveted nut is roughly the same as that of other screws. Only the screw is played out with the screw machine, and the nut is played out with the nut machine. To introduce the production process of pressure riveted nuts.

1. First, we must know what material and what material the riveted nut is, so that we can use what material to produce and what material to produce. Know what material and material to use, we can buy screw wire.

2. Determine the specifications and types of riveted nuts, and look at its size and length. In this way, it is good to use how much screw wire.

3. After determining what material, material, size and type, we need to see if it is a commonly used pressure riveted nut, if it is, there must be a corresponding mold in the factory. If it is not, it is not the target, then we have to order the mold.

4. After all the production is ready, the shape of the riveted nut, that is, the appearance, must be played out by the nut machine block.

5. After the pier is played, the tapping machine is used to tap the nut teeth.

6. After the tooth thread is tapped, the stainless steel riveted nut does not need to be electroplated, and only needs to be cleaned. If you want to electroplate other colors, you have to take it to a professional electroplating manufacturer for electroplating treatment.