There are many types of nuts, and many people cannot distinguish the specific functions of each nut, but all nuts can be used for industrial purposes and are widely used in the automobile manufacturing industry. Reed nuts are a very common type of nut in the automobile manufacturing industry and can be used in various parts of a car.

1. The concept and structure of the reed nut

The reed nut is a simple and reliable fastener that is widely used in various industries. When selecting a reed nut, it is necessary to select it based on factors such as the required workload, environment, standard and selection method to ensure excellent fastening effect and reliability.

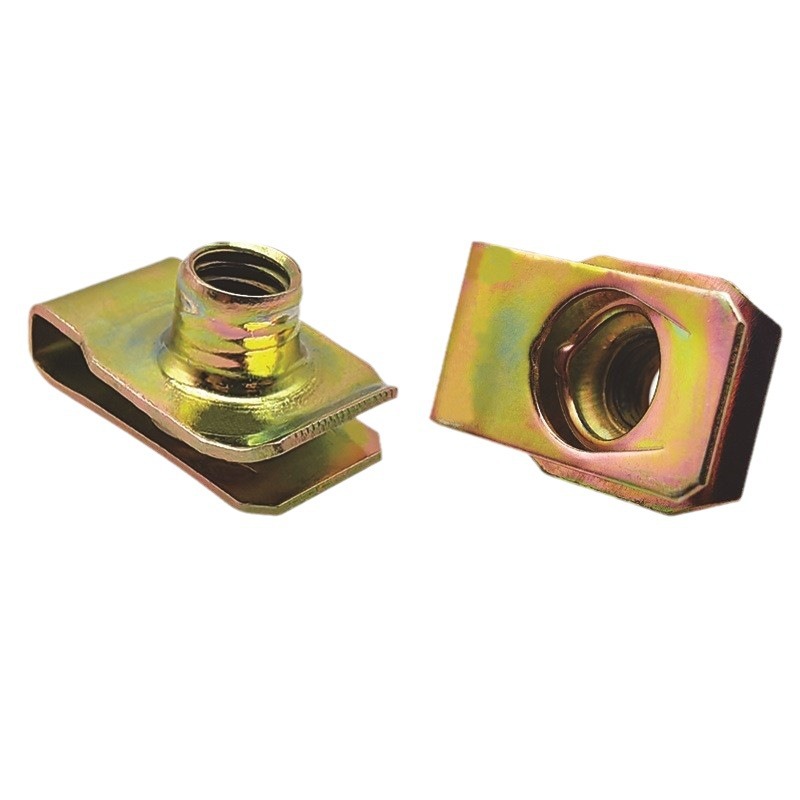

The reed nut is a common fastener that is often used to connect threaded parts of unconventional shapes. It consists of a set of curved and elastic thin sheets that can be bent and formed into a lock-like shape to provide stronger fastening force and anti-loosening effect. The structure of the reed nut is relatively simple, usually consisting of two parts, inner and outer. The inner part is the basic form of the nut, and the outer part is the elastic reed wrapped around the nut.

2. Application of reed nut

Reed nuts are commonly used in various industries, especially in machinery and construction industries. They are often used to connect pipes, parts with complex structures, such as card covers, wheels, etc. The advantages of reed nuts are easy installation and removal, maintenance, and prevention of loosening and falling off of connecting parts. At the same time, due to their relatively low material cost, they have good reliability and economy.

The specific functions are as follows

Tightening force of spring nut:

It is used to tighten the force between nuts, and can be used as a medium to tighten two parts. It is usually suitable for the tightening and stabilization of large parts.

Tightening and stabilization of spring nut:

It is used to stabilize the installation of nuts. It is usually quite convenient to operate and install. The appearance is relatively delicate and suitable for external structural parts of automobiles.

Spring nut is used in special situations:

It can withstand high pressure and can be used in special situations and environments.

Tightening effect of spring nut:

It can be used in situations where huge supporting force is required.

Squeezing effect of spring nut:

It is used to squeeze and open some spaces in some extremely narrow spaces to release gas.

Welding effect of spring nut:

It is used for reinforcement that must be melted and re-welded in some cases, and super-solid welding can be performed.

Load-bearing effect of spring nut:

In some cases, the object at the bottom cannot withstand huge pressure. At this time, adding a spring nut can withstand the force at the top.

Balancing effect of reed nut:

Under the unbalanced gravity of parts, the use of reed nut for adjustment can keep the overall effect balanced and relieve huge pressure.

Reed nut locking nut:

As a lock button for all parts, the reed nut can play a locking role under certain circumstances, locking and reinforcing the structure that is not very strong.

Protective effect of reed nut:

Under certain circumstances, the reed nut, as a special object in a special position, can be embedded in a specific position to prevent the parts from shaking in the original position and causing the overall structure to loosen.

Opening effect of reed nut:

Under special circumstances, the opening and closing nut can be used in some places to facilitate the opening of inconvenient parts during repair and disassembly.

3. Standards for reed nuts

There are many standards, such as American Standard, British Standard and International Standard. For general applications, such as general machinery, automobile and other industrial applications, ISO standard nuts are a more widespread and commonly used standard. The selection of leaf nuts should also take into account factors such as the required workload, number of thin slices, material and operating environment.

4. Selection method of reed nut

When selecting a reed nut, you need to select the appropriate standard, size, and material based on the application environment. If the required longitudinal or transverse load is higher than the working load of the standard reed nut, you can also choose a high-strength reed nut with increased load capacity. In addition, you should also refer to the manufacturer’s guidelines and specifications to ensure that the selected reed nut cooperates with other system components.

5. The difference between reed nuts and ordinary nuts

1. Structure and function of reed nut

Reed nut is a special nut structure, which is mainly composed of a metal spring sheet. The function of this spring sheet is to enable the nut to generate a certain tension during installation, so as to achieve a firm fixing effect. Reed nuts are mainly suitable for occasions that need to be disassembled frequently, such as pipe joints. The use of reed nuts can effectively reduce the friction loss and wear caused by repeated loosening of nuts, and can also shorten the installation and disassembly time.

2. Structure and function of ordinary nuts

Ordinary nuts are the most common type of nuts, and their structure is relatively simple. It consists of a metal threaded ring and a hexagonal nut body. Ordinary nuts are mainly used for connecting parts that require large forces, such as mechanical equipment, automobiles and other fields. During installation, tools such as wrenches or wrench sockets are needed to tighten to ensure that the connection is firm and stable.

3. Applicable scenarios of reed nuts and ordinary nuts

Due to their different structures and functions, reed nuts and ordinary nuts have different applicable scenarios. Reed nuts are mainly suitable for occasions that need to be disassembled frequently, such as water pipe joints, aircraft equipment, etc. Ordinary nuts are suitable for occasions that require a firm connection, such as vehicles, mechanical equipment, construction engineering and other fields.

4. Summary

Reed nuts and ordinary nuts are different in structure, function and applicable scenarios. For those who need to choose nuts, they should choose the appropriate nuts according to the specific situation. Familiarity with these differences can ensure the correct selection and use of nuts, thereby avoiding possible safety hazards.