Standard specifications and uses

DIN912 hexagon screws are also partially suitable for GB70.

DIN912 stainless steel socket head screw shape is round, also known as the cylinder head hex socket screws, the middle is hollow hexagonal. The head is knurled, and there is no knurled.

Hexagon screws with cylindrical heads are the most commonly used

In the production of stainless steel hex screws materials are SUS304 and SUS316 stainless steel two kinds.

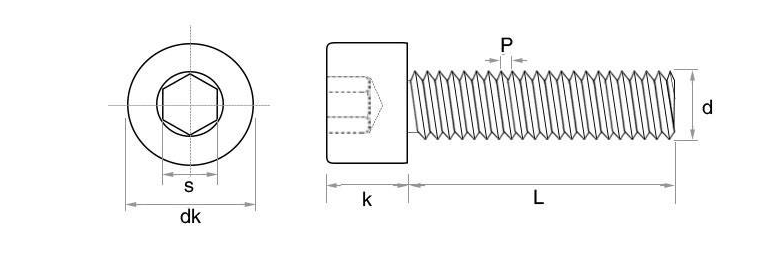

Socket head screws and full teeth and half tooth two kinds, such as shown in figure.

The half teeth were non-standard.

The production process of hexagon screws:

Socket head screws using cold heading process, first choose the right mold, in is heading, and then rubbing teeth in thread rolling machine, is in the test. To ensure that each socket head screws can be qualified to your customers. If it is a stainless steel hex screws and clean bright, carbon steel socket head screw to the plating processing, plating color can according to customer’s requirements.

Socket head screw drawing specification table:

The metric system specification table:

| Diameter(C) | screw pitch(P) | B | E | A | D | F | |||

| max | min | max | min | max | min | min | |||

| M3 | 0.5 | 18 | 5.68 | 5.32 | 3 | 2.86 | 2.58 | 2.52 | 1.3 |

| M4 | 0.7 | 20 | 7.22 | 6.78 | 4 | 3.82 | 3.08 | 3.02 | 2 |

| M5 | 0.8 | 22 | 8.72 | 8.28 | 5 | 4.82 | 4.095 | 4.02 | 2.5 |

| M6 | 1 | 24 | 10.22 | 9.78 | 6 | 5.7 | 5.14 | 5.02 | 3 |

| M8 | 1.25 | 28 | 13.27 | 12.73 | 8 | 7.64 | 6.14 | 6.02 | 4 |

| M10 | 1.5 | 32 | 16.27 | 15.73 | 10 | 9.64 | 8.175 | 8.025 | 5 |

| M12 | 1.75 | 36 | 18.27 | 17.73 | 12 | 11.57 | 10.175 | 10.025 | 6 |

| M14 | 2 | 40 | 21.33 | 20.67 | 14 | 13.57 | 12.212 | 12.032 | 7 |

| M16 | 2 | 44 | 24.33 | 23.67 | 16 | 15.57 | 14.217 | 14.032 | 8 |

| M20 | 2.5 | 52 | 30.33 | 29.67 | 20 | 19.48 | 17.23 | 17.05 | 10 |

| M24 | 3 | 60 | 36.3 | 35.61 | 24 | 23.48 | 19.275 | 19.065 | 12 |

| M30 | 3.5 | 72 | 45.3 | 44.61 | 30 | 29.48 | 22.275 | 22.065 | 15.5 |

Material of hexagon screws:

| The material of use | Element Name and Chemical Composition (%) | |||||||

| C | Mn | Si | P | S | Ni | Mo | Cr | |

| SUS304 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 8.00-11.00 | – | 17.00-19.00 |

| SUS316 | ≤0.08 | ≤2.00 | ≤1.00 | ≤0.045 | ≤0.03 | 10.00-14.00 | 2.00-3.00 | 16.00-18.00 |

The performance of the stainless steel hex screws and torsion standards:

| Category | Property class | Diameter of thread | Tensile strength | Yield strength Mpa | Elongation | Proof stress |

| A2 | 50 | ≤39 | 500 | 210 | 0.6d | 500 |

| A2 A4 | 70 | ≤24 | 700 | 450 | 0.4d | 700 |

| A4 | 80 | ≤24 | 800 | 600 | 0.3d | 800 |

The torsion standard:

| Thread | Performance rate | Performance rate | ||

| A2-50 | A2(A4)-70 | A4-80 | ||

| Damage to the torsion | ||||

| M1.6 | A2-50 A2-70 A4-70 A4-80 | 0.15 | 0.2 | 0.24 |

| M2 | 0.3 | 0.4 | 0.48 | |

| M2.5 | 0.6 | 0.9 | 0.96 | |

| M3 | 1.1 | 1.6 | 1.8 | |

| M4 | 2.7 | 3.8 | 4.3 | |

| M5 | 5.5 | 7.8 | 8.8 | |

| M6 | 9.3 | 13 | 15 | |

| M8 | 23 | 32 | 37 | |

| M10 | 46 | 65 | 74 | |

| M12 | 80 | 110 | 130 | |

| M16 | 210 | 290 | 330 | |

The use of hexagon screws:

Hexagon screws are widely used in the automotive industry, machinery, construction and other related industries.